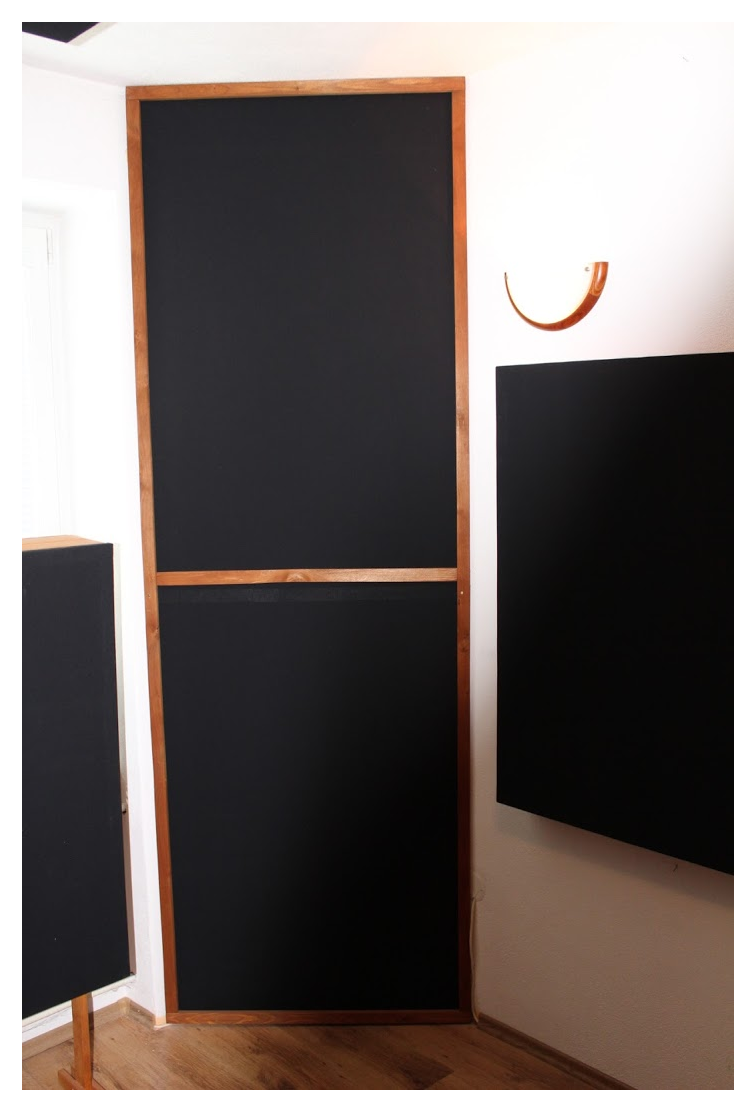

Corner Bass Traps

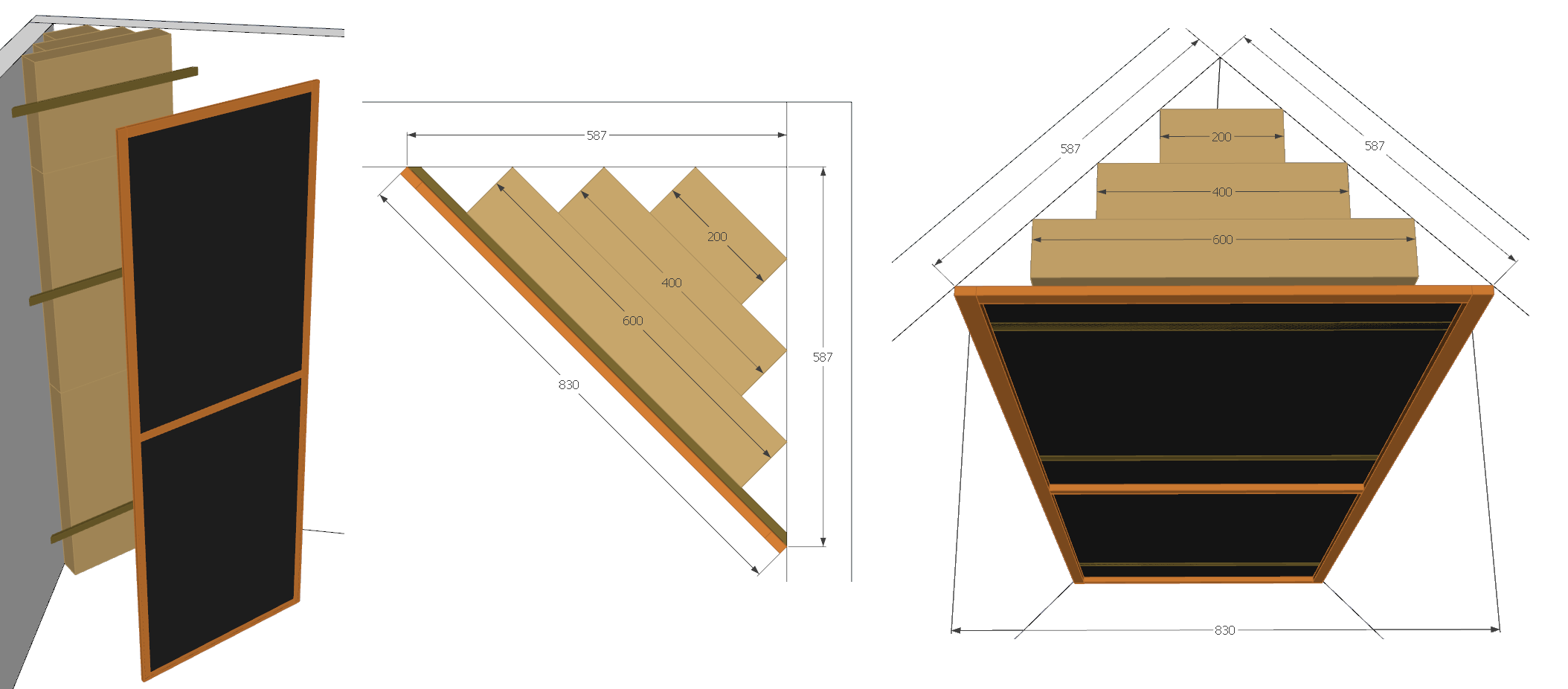

As described in the previous article the distortion on low frequencies is most significant in the corners of the room. When using your home or a small production or recording studios which are limited by budget it is often the design of simple DIY corner bass traps which is only one way of how to at least partially resolve this problem. One bass trap was made for each corner. The design of a corner bass trap is very simple and consists of three main parts:

Insulation panels

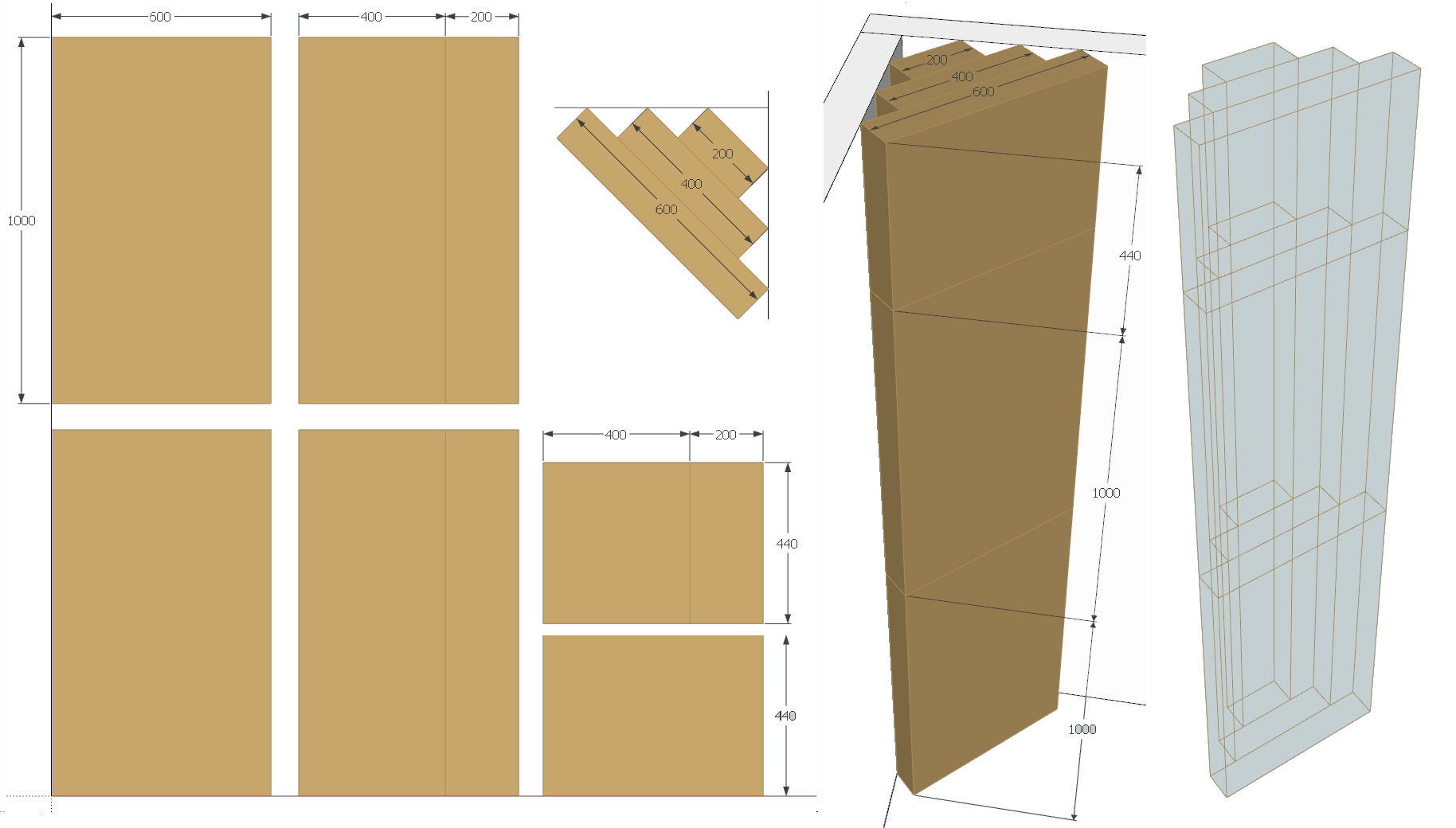

Because thermal insulation materials have also good sound absorbtion characteristic, they are ideal adept for cheap and simple acoustic solutions. On the market is wide offer. They alter by attributes and the price. Availability of certain products depends also on the region in which you live. After short research in my case was the choice Nobasil MPE. One bass trap needs 5 panels of this material (in the case your room is up to 2,50m otherwise at least 6 pieces). Manufactured panels of my choice are 1000x600x100mm of dimensions (100mm is thicknes). Two panels remained of original size, two panels was cutted off at the width by 20cm and height was retained, and last panel was cutted of also at the width by 20cm as two previous but because my room have 2,44m the height, the last panel had to be cutted at height to 44cm as well. For cutting I simply used old but sharp kitchen knife with 20cm long stab.

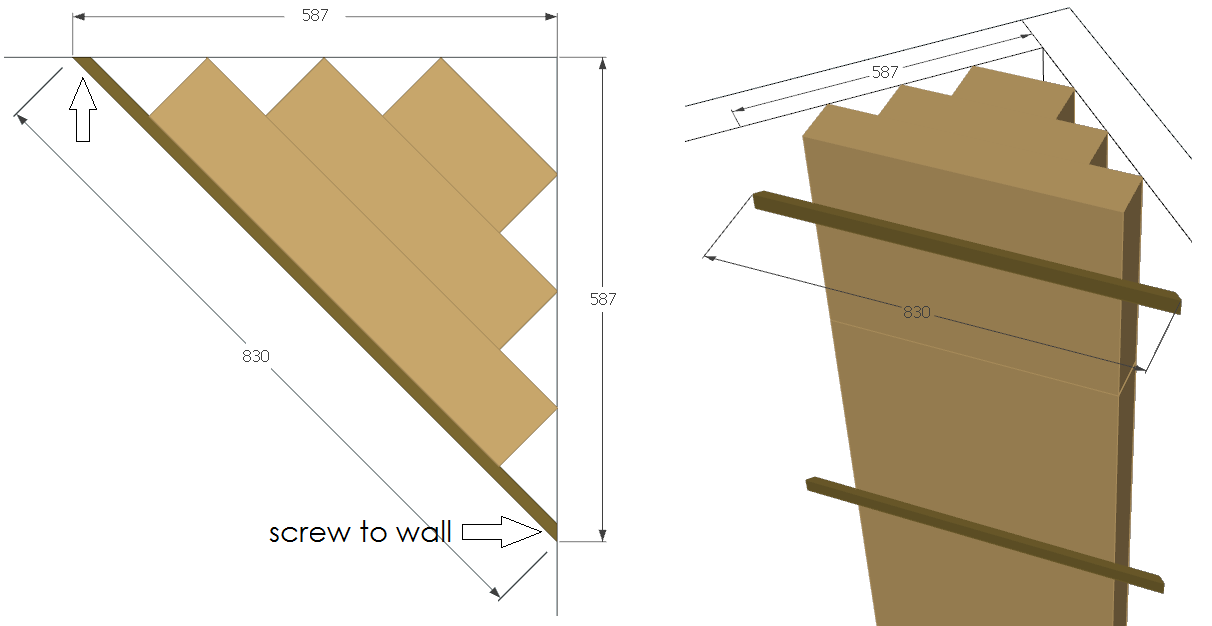

Cross holders

Holders are just wood lath of 33x15 dimesions cutted to 830mm length, lightly sanded. Holders are on the ends bevelled to 45 degree so they fit to the wall under the angle. Holders are used to keep the insulation on the place and also for attachment of the front frame. Holders are fixed to the wall by simple screws for wood. Type of anchoring of the screws into a wall depends on the material of a wall. In my case it is a brick wall with quite thick plastering. First attempt was to use a plastic anchor but during the installation I have found out that is enough to screw the screws straight through the holder directly into the wall, so I repeteated this simplified proceed for all remains screws. Each holder have two screw to attach to the wall, so bass trap need just 6 pieces.

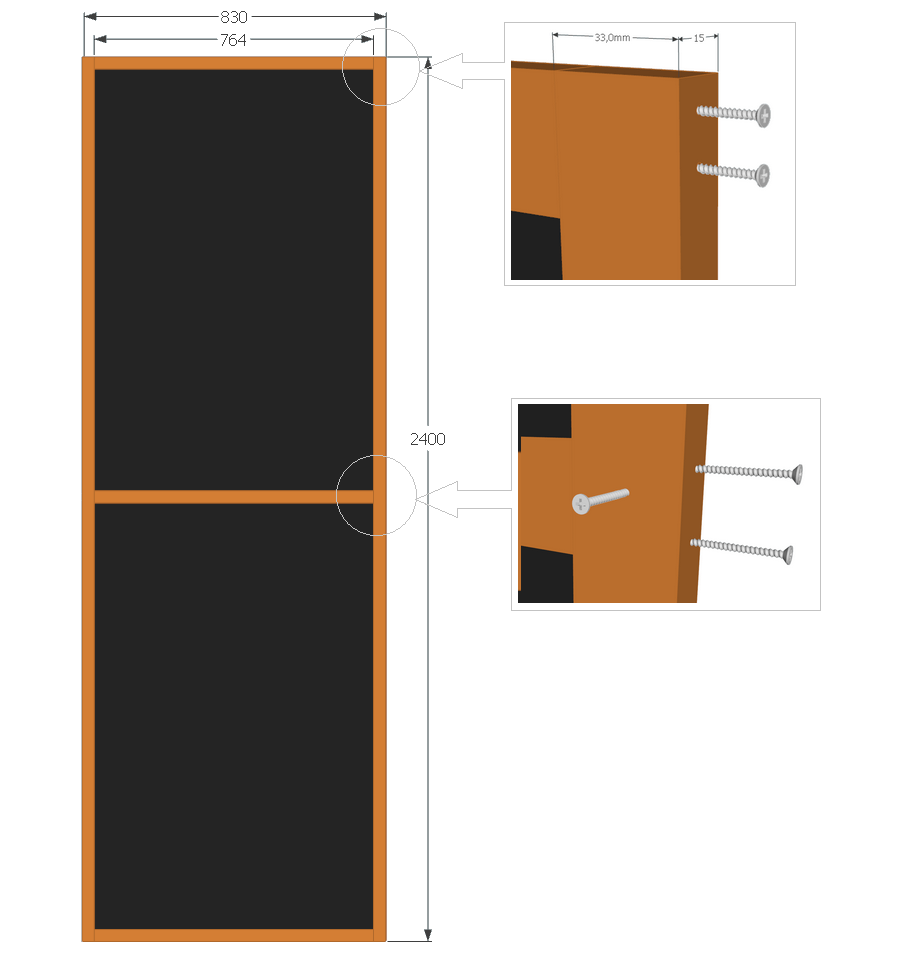

Front frame

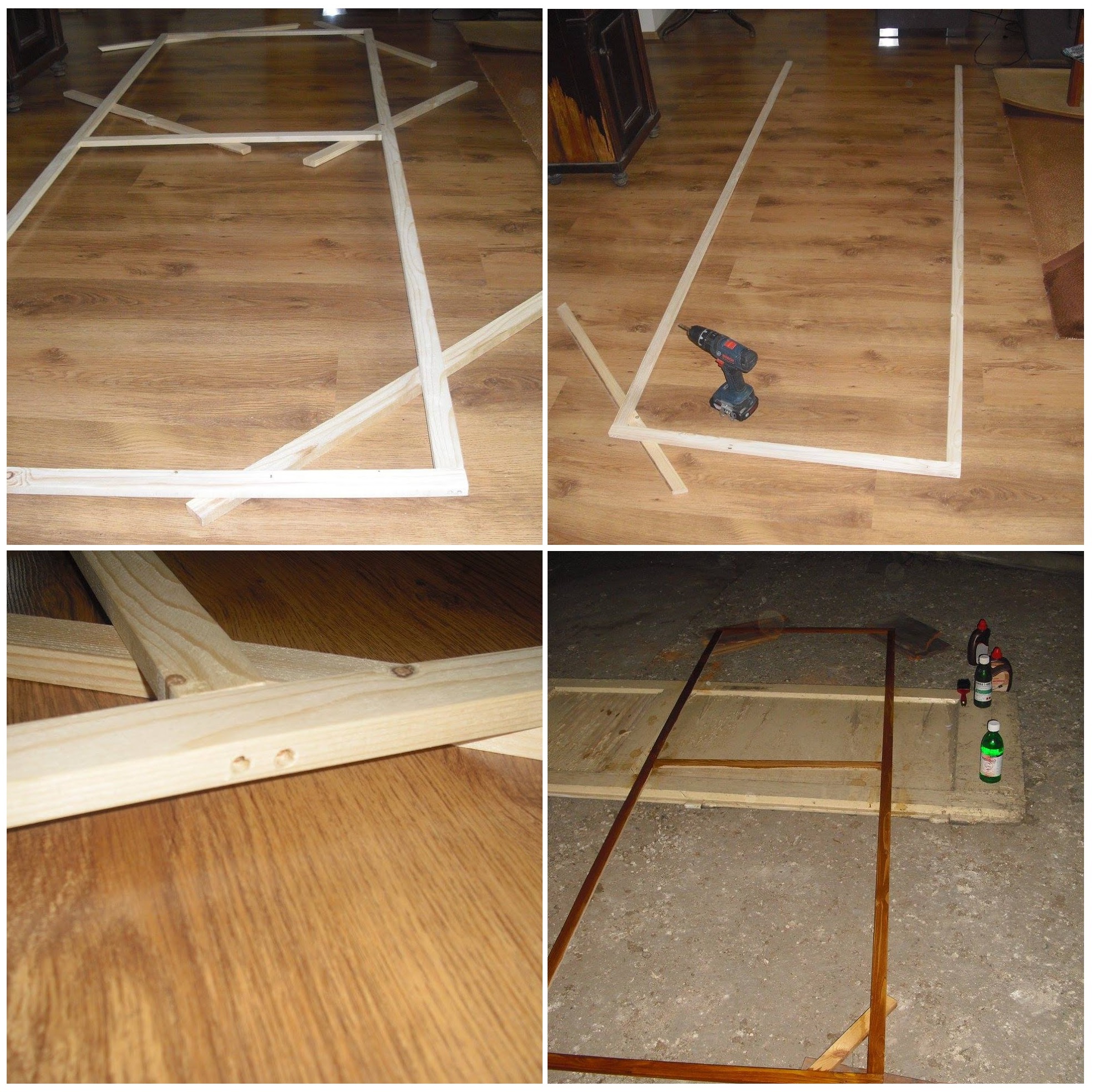

Front frame is again made by wood lath of 33x15 dimensions. From inner side is used fabric of 135 g/m2 density, fastened to the frame by electrical stapler. Length / Height of the frame is in my case 2400mm what is equal to the high of my room. Frame is joined together by wood screws 3x5 then sanded and from the front side also stained and varnished. Fabric is then stamped to the frame from the back side. Assembled frame with fabric cover is attached to the holders by two screws in the middle of the frame. First I intended to use six screws, to each corner and to the middle, but after mount of first two screws in the middle (one on each side) I decided that is no need more screws.

Here are the dimensions of the one frame: